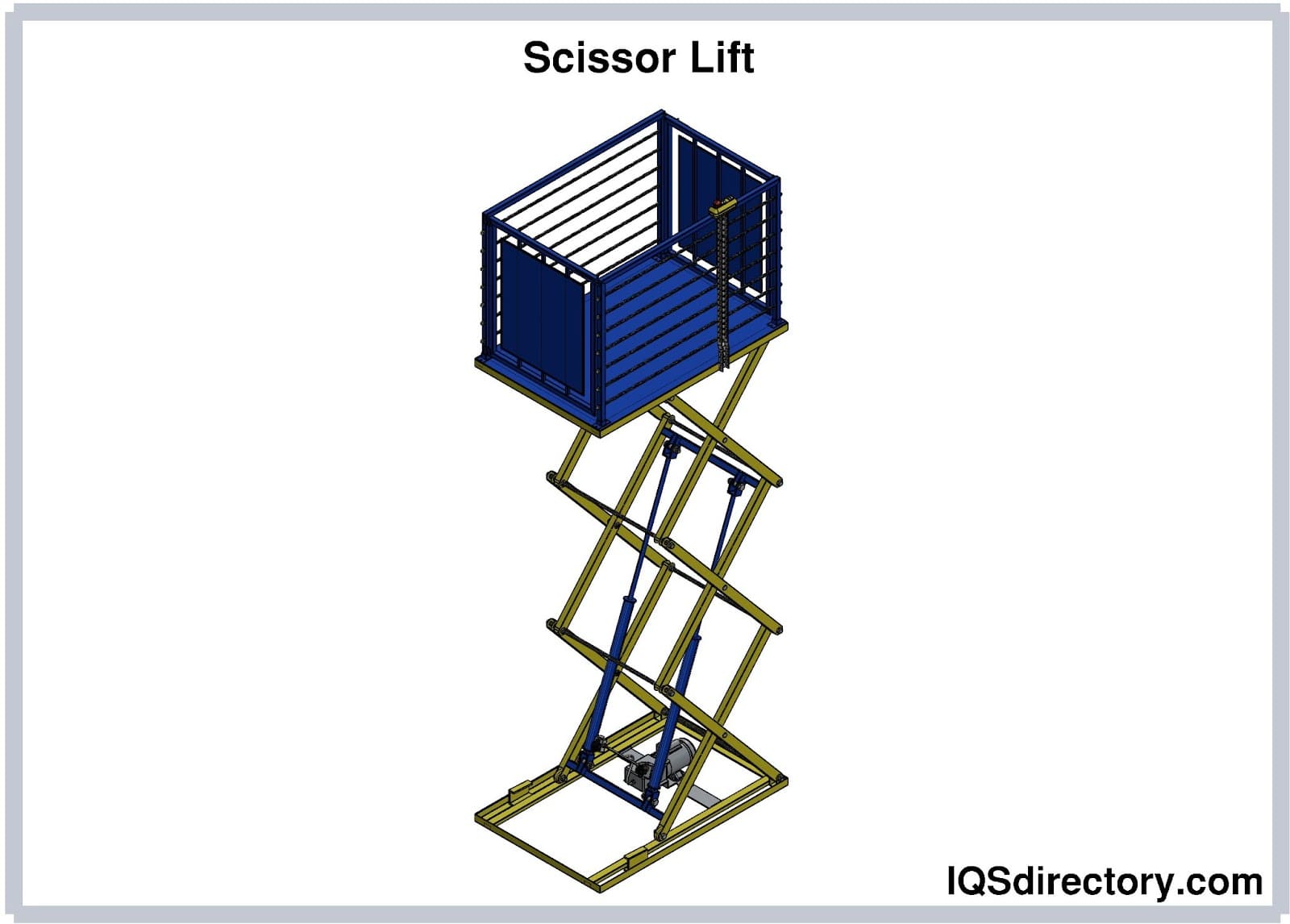

The machine uses a motor that exerts hydraulic pressure to raise and lower the unit’s moving scissor arms. The hydraulic pressure moves a piston on a long cylinder beneath the table, causing the table to go up or down as the pressure is increased or decreased using electronic controls. A scissor lift table can be made to extend anywhere from just a few inches to many feet. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Scissor Lift Table Manufacturers

Sometimes the lift mechanism of a basic table is not motorized at all, and hydraulic pressure is applied by pumping a foot pedal. This reduces the overall weight of the scissor lift table, but it also limits the lifting power of the unit.

Scissor lift tables are a valuable tool in an industry where heavy objects need to be lifted and moved. Sometimes human force can accomplish the same task, but if it were to be done repeatedly the weight would quickly cause injury and wear out most workers. Rather than create unnecessary work and injury, a scissor lift table makes lifting easy and efficient.

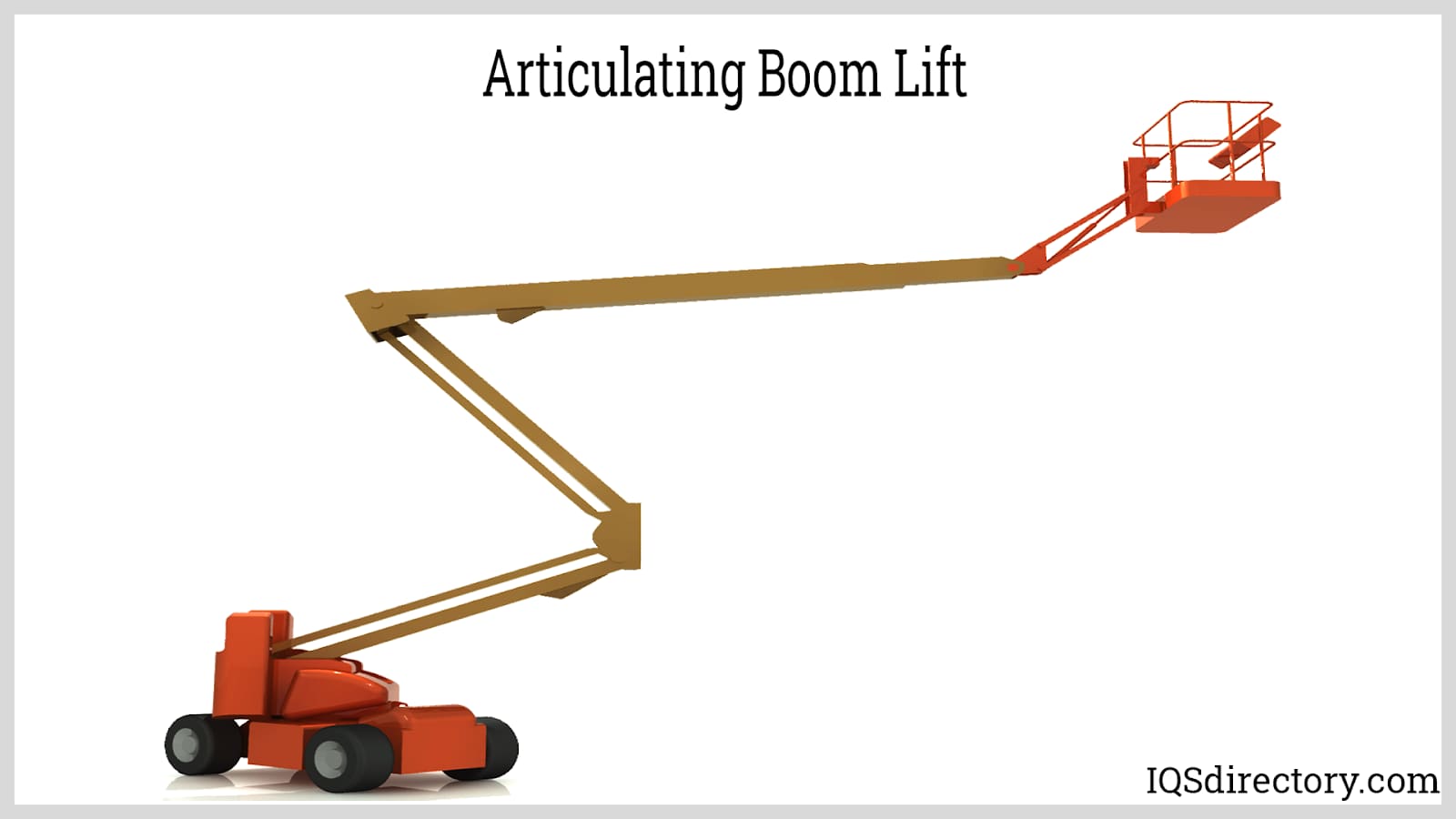

Many scissor lift tables are fitted with wheels on the bottom of the sturdy metal frame to allow for easy movement across flat surfaces. This means that a table can be moved around in industrial settings to meet the needs of a particular project. A scissor lift table uses the same technology that a mobile lift on a construction site uses.

The weight capacities of scissor lift tables vary based on design. A basic scissor lift table usually has a weight capacity of only 500lbs. On the other end of the scale, a heavy duty scissor lift table is built with the ability to lift thousands of pounds.

There is a big cost difference between these two capacities, but most manufacturers also offer a range of products that are somewhere in the middle.

Scissor lift tables are used in many industries to change the elevation of machinery, provide a space for packaging products, or installing heavy parts like a transmission in industrial machinery.

Jumbo Scissor Lift Table - Advance Lifts, Inc.

Jumbo Scissor Lift Table - Advance Lifts, Inc. Order Picking Scissor Lift Tables - Advance Lifts, Inc.

Order Picking Scissor Lift Tables - Advance Lifts, Inc.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

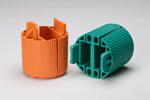

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services