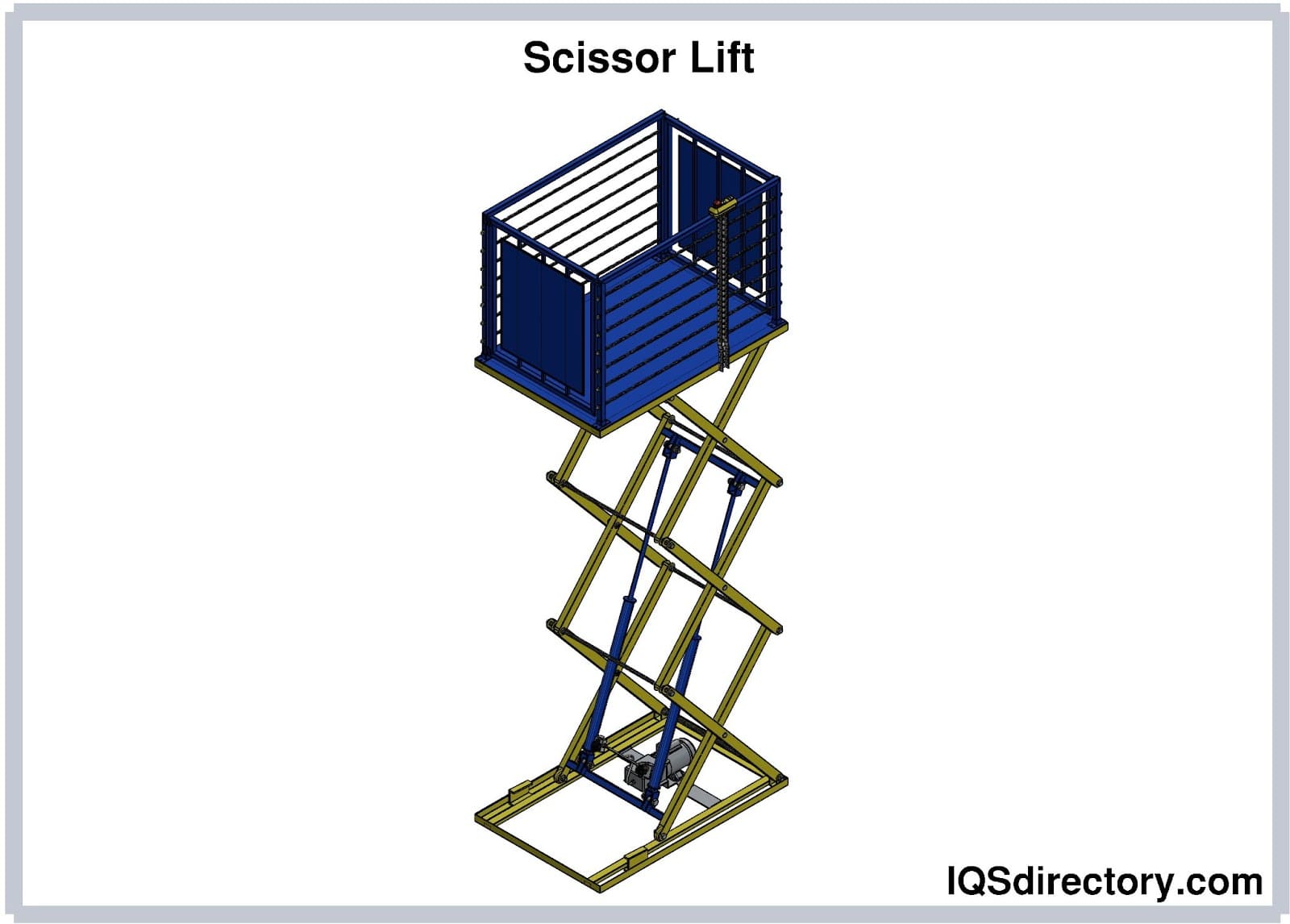

A scissor lift is a device designed to move people and objects vertically. These lifts can handle any application that typically requires a ladder, tower, or scaffolding. The term scissor lift refers to the design of the lifting mechanism, which consists of a cross-shaped stack of tubes that operates like a scissor when raising and lowering the platform. The majority of scissor lifts are self-propelled machines. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Scissor Lift Manufacturers

As pressure is applied to the lowest set of supports, the remainder of the structure enlarges as it goes higher. When sliding downward, the other supports retract as the pressure on the lower supports is reduced. As a result, scissors lifts allow users to carry out the same tasks more quickly and safely without the need to set up additional equipment like scaffolding or a tower, as well as without the risky instability of a ladder.

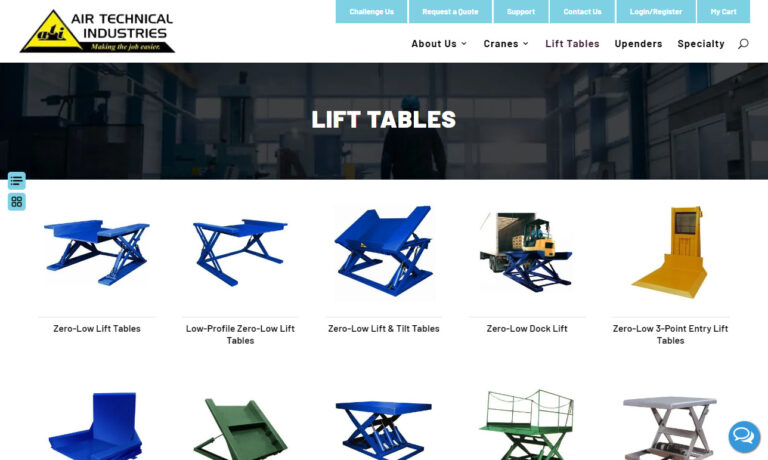

Types of Scissor Lifts

Electric Scissor Lift

Aerial platform machines with electric scissor lifts are another common type. Electric scissor lifts have a silent, powered drive system as an alternative to burning fuel. As a result, electric scissor lifts offer a cleaner option for inside environments, which frequently lack enough ventilation because they don't produce noise or emissions. These machines are ideal for smaller settings because they are less substantial than diesel equivalents.

Hydraulic Scissor Lift

Hydraulic systems driven by an engine or operated manually power hydraulic scissor lifts. The hydraulic oil in the device's hydraulic system changes pressure to enable the scissor lift to move up or down as needed. Users don't need to undergo much training to utilize a hydraulic scissor lift, making it a straightforward solution when you need to lift something. Hydraulic scissor lifts are useful for usage in infrastructure projects, construction sites, and warehouses. The scissor lift users turn on the power supply. Workers can use small, portable hydraulic scissor lifts to transport cargo or heavy objects around a factory or workshop.

Rough Terrain Scissor Lift

Additionally, rough terrain scissor lifts are made specifically for outdoor terrain. They include heavy-duty tires, a large weight capacity, and extra safety features like fall restraints and arrestors. They are, therefore, perfect for projects carried out in bad weather. These scissor lifts are additionally made to operate in adverse weather conditions and on slopes. Scissor lifts for rough terrain can reach heights of up to 50 feet (15.2 meters) and widths of up to 10 feet (3 meters). Diesel, gasoline, liquid propane, or multiple fuels power the equipment.

Diesel Scissor Lift

On building sites, diesel scissor lifts are among the most popular. Due to their peculiar cross-braced design, they can reach heights of up to 30 feet (9.1 meters), with some examples reaching 60 feet (27.4 meters). A diesel lift is noisy and releases fumes into the air because it is powered by conventional diesel fuel.

However, the wider platforms of the diesel scissor lifts make them ideal for outdoor construction projects, well-ventilated interior spaces, and locations where critical staff communication won't be hindered or distracted by engine noise. In addition, workers can use diesel scissor lifts for various tasks, including warehouse, retail, point of sale, and cleaning.

Pneumatic Scissor Lift

The lifting technique of pneumatic scissor lifts is reliant on airflow. This lift is more environmentally friendly than regular lifts since it doesn't release harmful byproducts or gasses into the environment, helping businesses reduce their carbon footprint. They are excellent for businesses that want to operate sustainably and with a smaller carbon impact because they raise and lower the lift using air pressure.

The atmosphere is compressed and vacuumed using a pneumatic scissor lift. They offer less power than rough terrain or diesel lift because they need fuel. However, the equipment can be used in nearly any setting, including interior facilities, as they only need air.

Applications of Scissor Lifts

- Altering lights, hanging banners, laying bricks, pouring concrete, changing signs, and accessing utilities are just a few jobs that call for working high in the air since they enable employees to complete duties.

- Securely, scissor lifts are a common option in building maintenance.

- For dynamic construction projects that could have regularly changing conditions, scissor lifts offer a mobile, adaptable option.

- Scissor lifts are best used for tasks that require vast heights and large loads that cannot be handled by hand, and they are frequently used at busy shipping hubs to distribute goods.

- Manufacturing industries use scissor lifts. An aerial platform can increase operating efficiencies by swiftly and safely ascending to great heights and hauling huge cargo.

- Storage businesses must effectively utilize all vertical and horizontal space. Scissor lifts can significantly enhance the success of such businesses.

Benefits of Scissor Lifts

Since some lifts may reach heights of up to 32 feet (9.8 meters), scissor lift technology allows workers to access areas that would otherwise be extremely difficult to reach. The smallest type of aerial work platform that one can find is a scissor lift. This is significant in confined locations, such as event venues or densely populated warehouses where stacked boxes restrict access at a height.

Scissor lifts are among the most portable lifting equipment, but other aerial work platforms need a lot of floor space. These lifts are simple to store because the total space needed is about equal to the platform size that one can raise.

Scissors are undoubtedly the most cost-effective and adaptable choice out of all options. With just one vertical lift, workers may service an entire warehouse. Additionally, hydraulic lifts use virtually no power, thus enhancing their efficiency.

Choosing the Proper Scissor Lift Manufacturer

To ensure you have the most productive outcome when purchasing a scissor lift from a scissor lift manufacturer, it is important to compare several companies using our directory of scissor lift manufacturers. Each scissor lift manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each scissor lift business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple scissor lift companies with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services