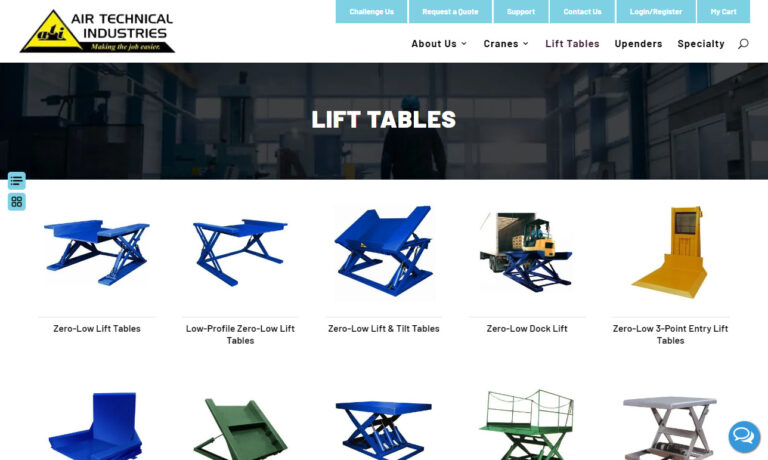

They can be used to load and lift non-pallet-mounted materials as well. Pallet lifts are typically used in warehouses, loading docks and anywhere else pallets need to be efficiently picked, transported, and stored. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Pallet Lift Manufacturers

The need for pallet storage and pallet movement equipment is universal, but the market is diverse, and the needs of one manufacturer or distributor will be different from another.

For example, a small-scale second hand book distributor may not need a forklift or hi-low to move pallets of books; a small hydraulic lift like a pallet jack may be sufficient for that operation's pallet movement needs. On the other hand, a large scale apparel wholesaler with multi-level stock racks will need a mechanized pallet lifting system that can reach high racks and support heavy loads.

Manufacturers, service companies, distributors and all kinds of other industrial operations, as well as operations outside of industry, require access to pallets and pallet movement equipment.

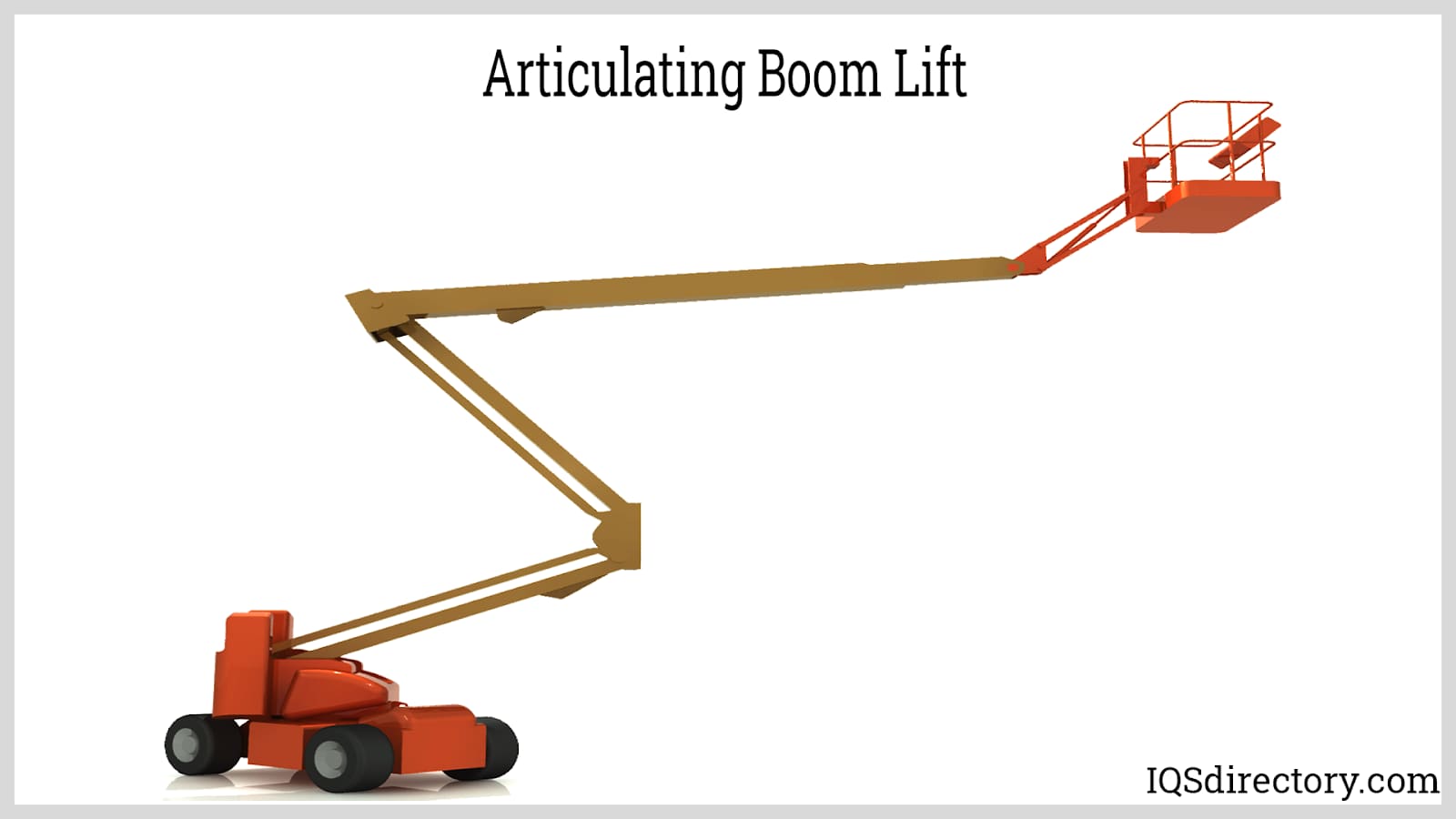

Fork lift trucks, reach trucks and several other gas or electricity-powered, heavy duty hydraulic lifting systems are available in many configurations for such operations.

Pallets are storage platforms used by manufacturers to ship their products; they are also used by warehouse operations, retailers and many other operations to store and display products. They can be made of wood, plastic, metal and other materials. They are characterized by their semi-hollowness; each hollow area in a pallet is designed to allow access to a lifting tool. Because few if any pallets are designed with a specific lifting mechanism in mind, every pallet lifting tool resembles every other tool, at least in terms of the shape of its pallet lifting implements.

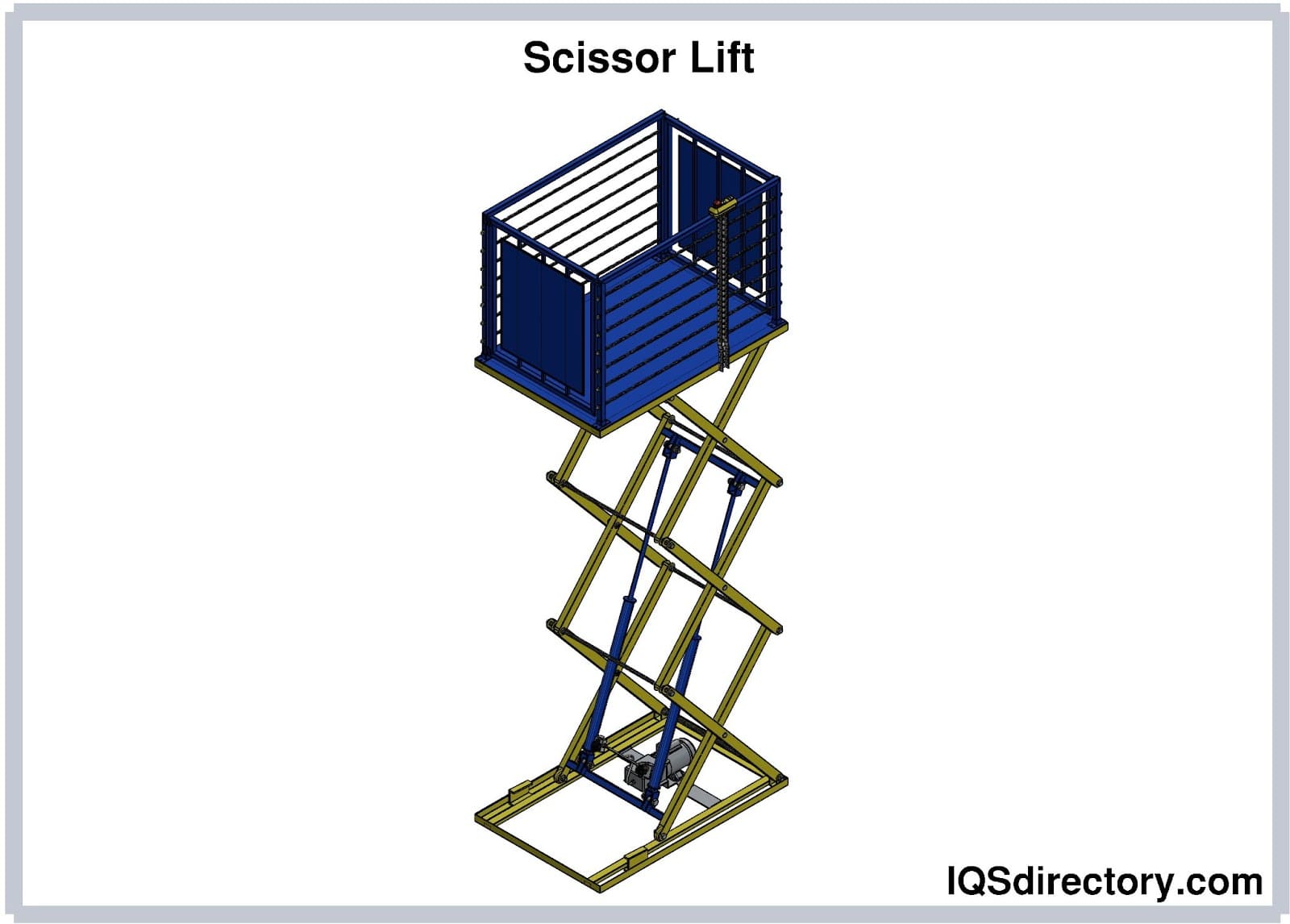

Manual pallet jacks operate by the same principle as larger, mechanized pallet jacks. A manual pallet jack features a forked lifting surface, wheels and a hydraulic lifting system.

When a manual pallet jack is used to lift a pallet, the forks are slid into the pallet's hollow area. Then, the user pumps the jack's handle, which forces hydraulic fluid into a cylinder in small amounts, gradually forcing up a piston in the cylinder, which is connected to a rod that is attached to the lifting surface.

When the pallet has been moved and must be set down, the user releases the pressure in the cylinder, which causes the load to be lowered gently. Mechanized pallet lifts operate according to the same principles.

They are distinguished, though, by higher mobility, higher lifting capacity and the ability to reach pallets in high places.

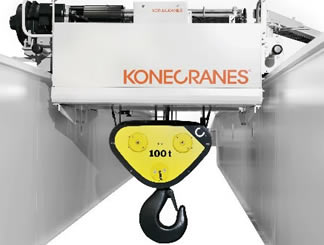

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services