Industrial turntables are a type of lift used in commercial and industrial applications. In manufacturing and production contexts, industrial turntables provide a rotating platform, for example with items stationed on the platform at intervals. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Industrial Turntable Manufacturers

As each item passes a production station, as on an assembly line, work may be performed on it. Turntables come in a large variety of configurations, and may be powered or manually operated. Industrial turntables are used in factories, warehouses, and in many different applications, from automotive to food production.

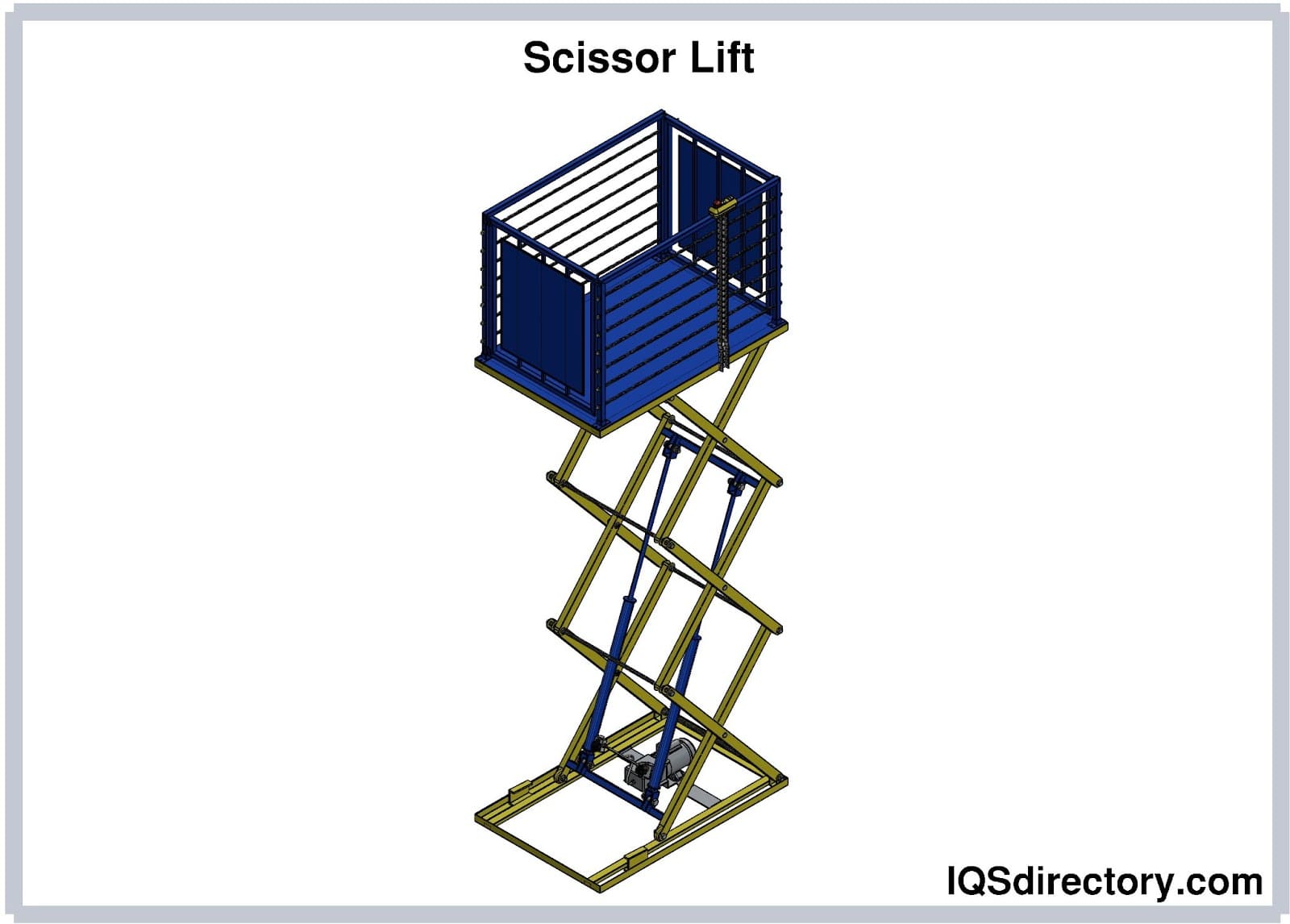

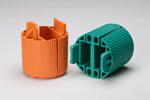

Turntables may be either standard duty or heavy-duty ring bearing. Standard duty turntables are more economical and offer better value for most industrial applications that are not too demanding. Heavy-duty ring bearing turntables offer more accurate positioning, higher capacity and more stability. Platforms on turntables may be standard or reinforced. Conveyors can be mounted onto turntable platforms. Turntables can be powered by pneumatic air or electricity, and some varieties offer adjustable legs and casters for rolling the unit from place to place and balancing loads on uneven surfaces.

There are three main ways that loads are placed onto industrial turntables: edge loading, sliding loads on and off, and lifting or stacking loads onto the turntable. Items may be loaded onto the turntable platform with forklifts, wheeled carts or vehicles, or crane-like machines. Loads can also be placed on turntables via sheet feeding or conveyor operations. The capacity of an industrial turntable is the total weight placed on it. This is the sum of the live load weight and dead load weight, where the live load weight is the total weight of the items placed on the turntable and removed from it, and the dead load weight is that of any fixtures, conveyors or other equipment permanently attached to the turntable platform.

Industrial turntables have a vast array of uses. In factories and production facilities, they can rotate piecework items on a platform so that as each passes by a worker or robot, work is completed on that piece; then, the platform rotates the next item to be worked on to that station on the assembly line. For food production processes, industrial turntables can be fitted with scales to weigh product, and turntable platforms can be made with holes to allow water or other liquids to drain off the product. Some turntables have variable speed settings and can rotate either clockwise or counter-clockwise, while others may have platforms that can be lowered or raised, either manually or via a power source. Turntables can make production processes more efficient, as loads can be placed onto the turntable while others are being worked on, at the same time.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services