Industries that require the repositioning and movement of large types of supplies and loads rely on upenders as an essential means for saving time and labor. The design and engineering of these load shifting devices make it easy, convenient, and efficient for shifting raw material and positioning them for immediate use. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Hydraulic Upender Manufacturers

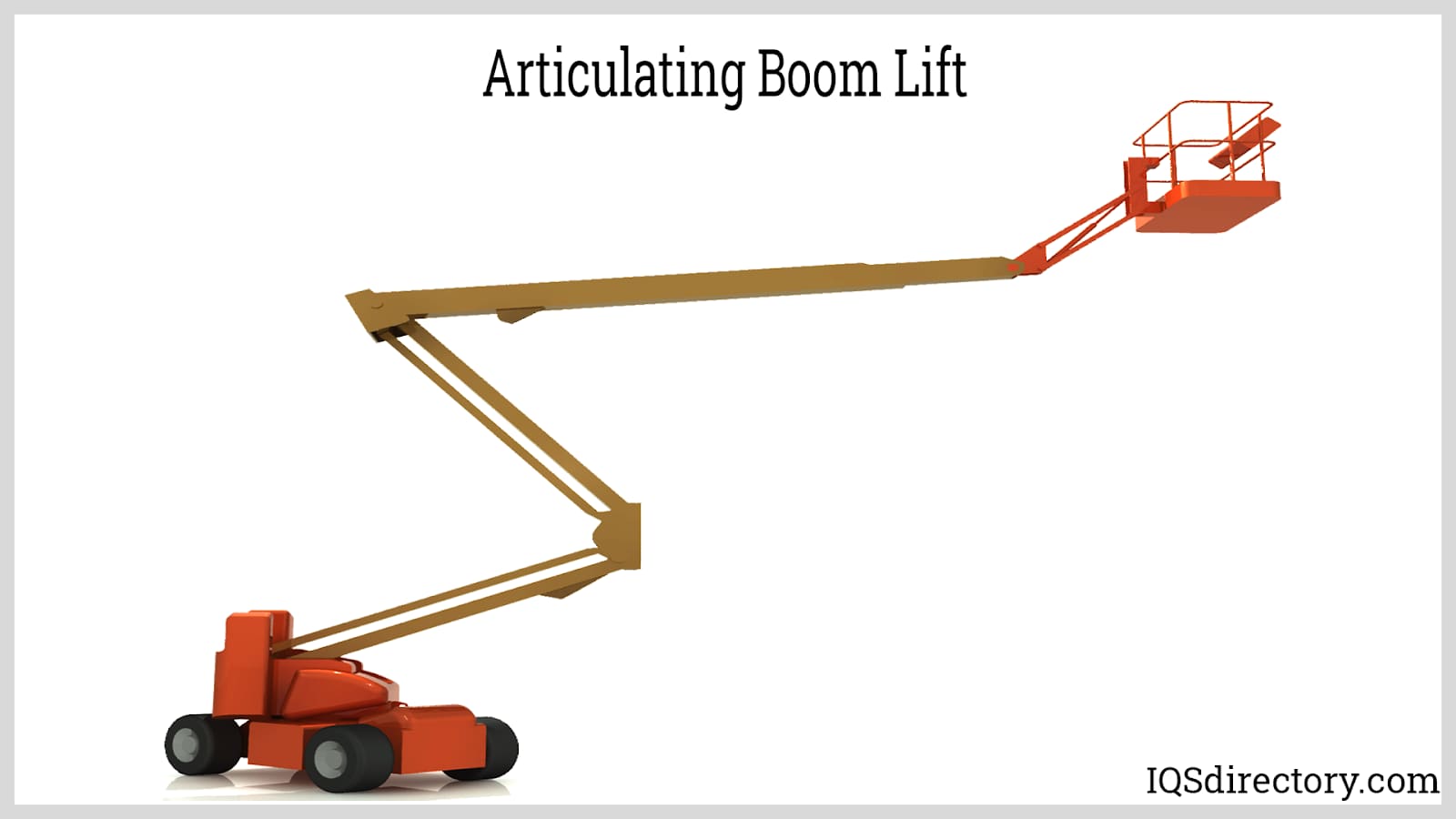

There are several industries that deal with supply items that are either exceptionally cumbersome or extremely heavy. In the past, the movement of such unwieldy materials required the installation and use of an overhead crane. Though such solutions are still being used, they are unnecessary for small operations or repetitive loading. These in-between conditions have led to the development of the upender.

What is an Upender?

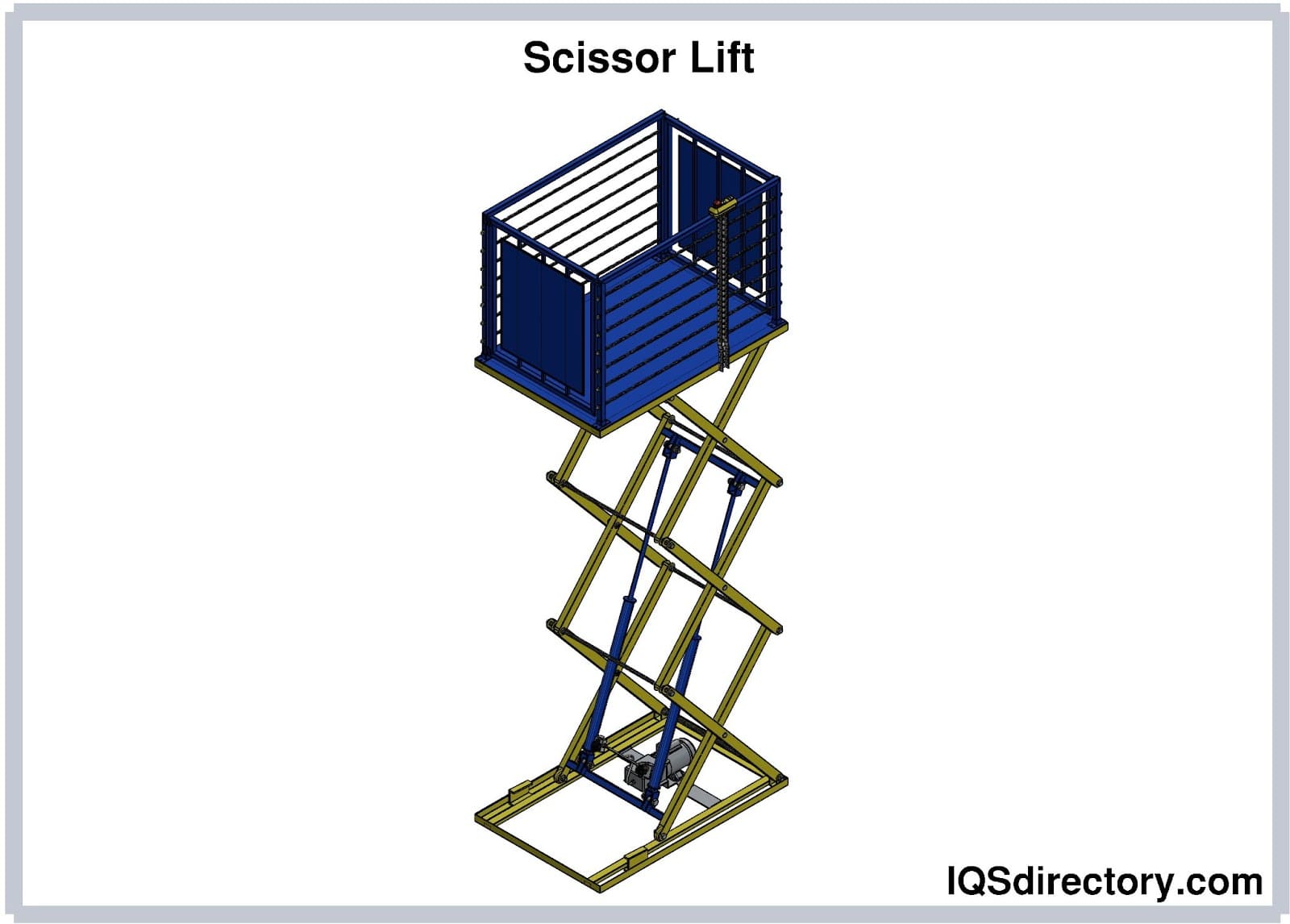

In the simplest of terms, it is a device that is designed to flip, turn, rotate, and reposition any number of extremely heavy loads. This sturdy hydraulic piece of equipment uses a motor and a hydraulic pump system consisting of several evenly positioned lifting pumps to turn and move otherwise immovable materials.

Items, such as coils, heavy paper rolls, trucks, wire rolls, and molds, are impossible to lift and move using traditional methods like forklifts. The sheer weight of these items makes it impossible to use anything except some form of heavy-duty equipment. For materials that are not heavy but cumbersome, it is impractical and inefficient to use manual labor.

It is for these various and unique conditions that hydraulic upenders were engineered and developed. After a load has been placed on the platform, a simple activation of a button rapidly, smoothly, and efficiently shifts the position of the load for practical manipulation.

What is the Design of an Upender?

As with any form of industrial equipment, upenders come in a wide variety of shapes, sizes, and load capacities to fit specific material movement requirements. Each of the many designs are created to accommodate the needs of an application with ones that are capable of lifting trucks to ones that reposition and shift paper roles. The number of uses and kinds of these technically efficient devices are limitless and ever growing.

The one basic factor that is prevalent in all forms of hydraulic systems is the need to lift and turn loads. The hydraulic capacity of each type varies between a few thousand pounds up to hundreds of tons depending on the needs of the application.

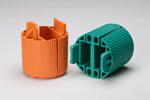

Platforms for upenders can be flat or table like, or V shaped. Flat ones are developed to handle loads with a flat base or ones that are on wheels. V shaped platforms are for unusually shaped loads that do not have a base or are cylinder shaped.

The convenience, efficiency, and easy access of these highly technical and useful pieces of equipment has made them an essential part of material, storage, and supply management.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services