Systems that rely on hydraulic power operate based on the principles of fluid mechanics, meaning that fluids are stored under pressure; when force is applied to one area it is transmitted to another area by means of the fluid. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Hydraulic Lift System Manufacturers

Hydraulic Lifts: Comprehensive Guide to Applications, Benefits, and Selection

The use of hydraulic fluid makes this process highly efficient, and the force that is applied is in almost all cases multiplied, which makes hydraulic lifts popular for heavy-duty applications and a critical component in modern material handling, industrial automation, and vertical transportation solutions.

What Are Hydraulic Lifts and How Do They Work?

Hydraulic lifts are mechanical devices that utilize the power of pressurized hydraulic fluid to generate lifting or lowering motion. These systems typically rely on basic components such as hydraulic pistons, pumps, cylinders (or rams), and a power source—most often an electric battery or motor. The application of force through hydraulic fluid allows for the multiplication of lifting power, making these lifts ideal for managing substantial loads with minimal manual effort.

How do hydraulic lift systems operate? The process begins with the power source (AC or DC electric motor, or even internal combustion engines in some industrial contexts) activating a hydraulic pump. This pump pressurizes hydraulic fluid, which then moves into a cylinder, pushing a piston upward or downward. The movement of the piston translates into vertical or horizontal lift, depending on the lift’s configuration. Excess hydraulic energy is stored in accumulators, ensuring consistent performance and safety even during fluctuations or power loss. This simple yet robust mechanism is what gives hydraulic lifts a distinct advantage for many challenging lifting and positioning tasks.

Key Industries and Use Cases for Hydraulic Lift Systems

Hydraulic lift systems are frequently utilized in industries such as:

- Automotive: For parking lift systems, vehicle elevators, car lifts, hydraulic jacks, braking systems, and other power transmission applications. Automotive repair shops often rely on hydraulic lifts for car maintenance and tire changes, while multi-level parking garages use them for efficient space utilization.

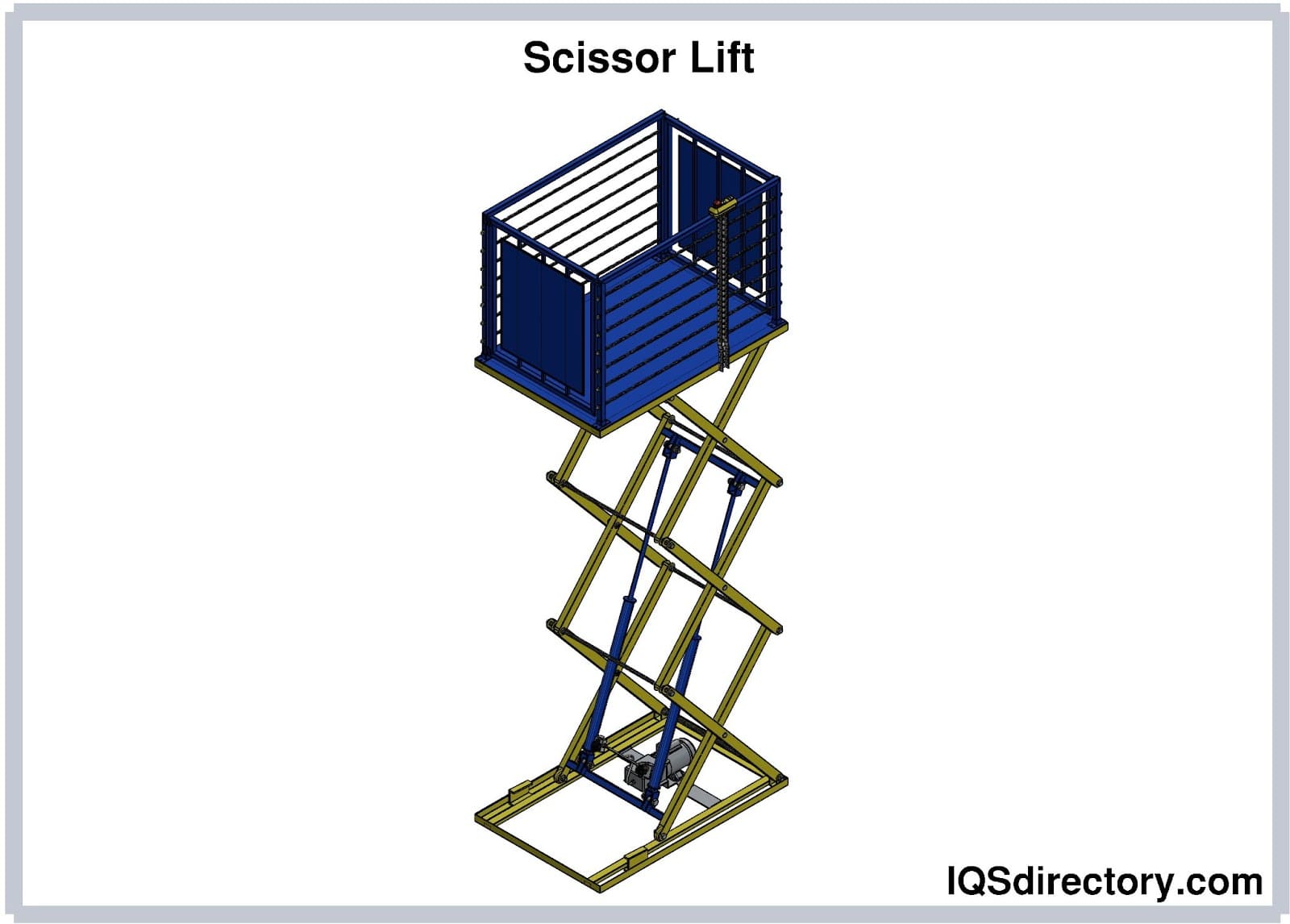

- Industrial Manufacturing: In a variety of process and assembly machinery, including conveyor systems, material handling lifts, pallet lifts, and scissor lifts. Hydraulic lifts are integral for moving heavy equipment, loading/unloading, and assembly line automation.

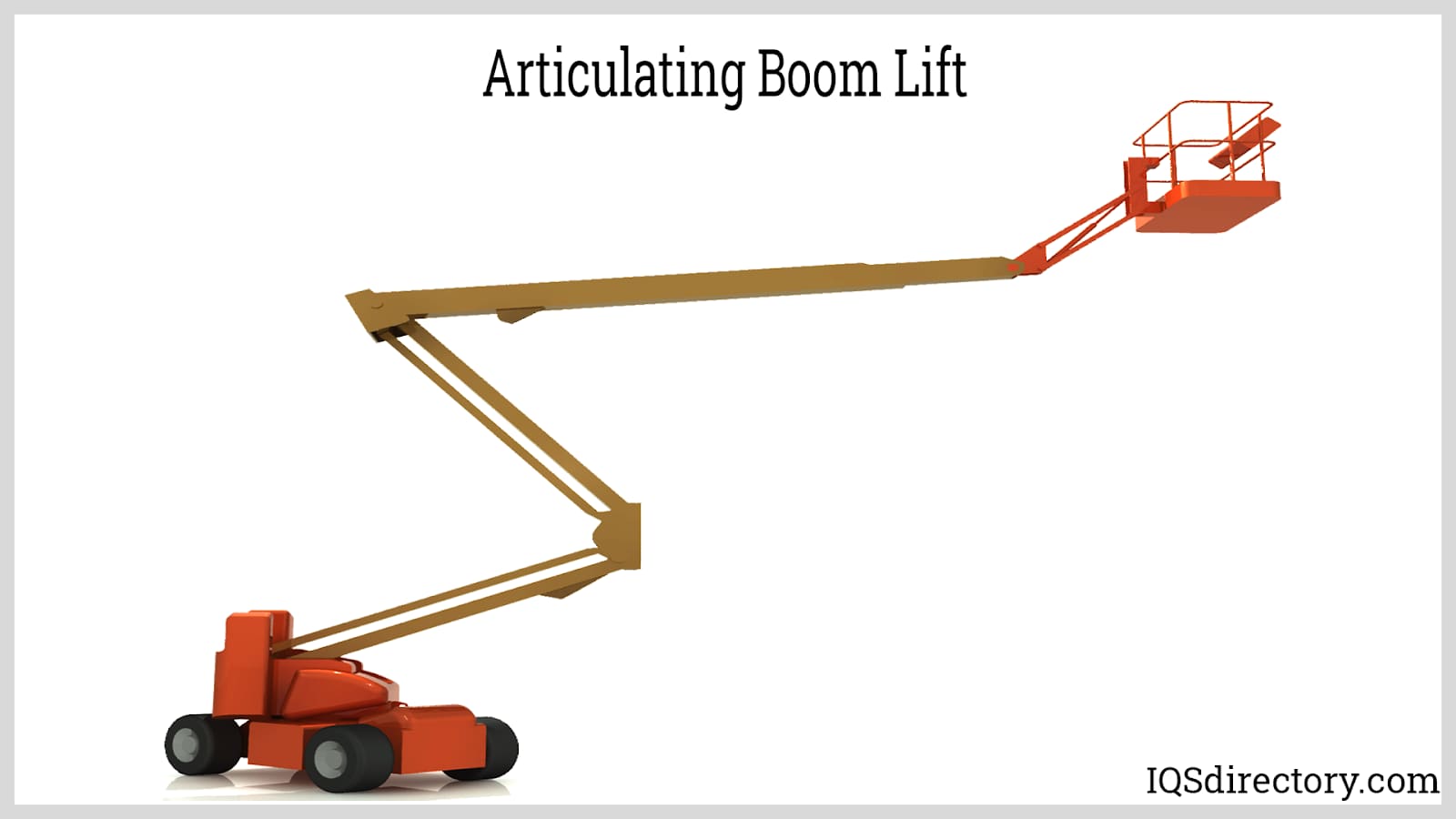

- Construction: For lifting and positioning heavy building materials such as concrete, stone, steel beams, and brick. Construction lifts, bucket trucks, and hydraulic cranes leverage hydraulic power for safe and precise operations at job sites.

- Steel Mills: For the transport, processing, and handling of steel and other heavy metals. Hydraulic lifts are vital for moving large, dense materials efficiently in environments demanding both strength and reliability.

- Marine and Offshore: Applications such as off-shore mining, off-shore pipelines, shipbuilding, and maintenance, as well as steering and braking systems for marine vessels. Marine hydraulic lifts are also found in cargo handling and subsea operations.

- Agriculture: For positioning combine headers, plows, and other heavy equipment. Hydraulic lifts in agriculture streamline planting, harvesting, and maintenance tasks, improving productivity and operator safety.

- Medical and Accessibility: In hospitals, clinics, and residential settings, smaller hydraulic lifts are used for patient transfer, bed lifts, wheelchair lifts, and scooter lifts, enhancing mobility and patient care.

- Warehousing and Logistics: Hydraulic dock lifts, scissor lifts, and freight elevators play a crucial role in loading, unloading, and transporting goods within distribution centers and warehouses.

Types of Hydraulic Lifts: Matching Solutions to Your Needs

Hydraulic lift systems are available in a wide variety of configurations, enabling them to be adapted to fit the specific requirements of any application. Understanding the major types of hydraulic lifts can help you select the ideal solution for your lifting and transport challenges:

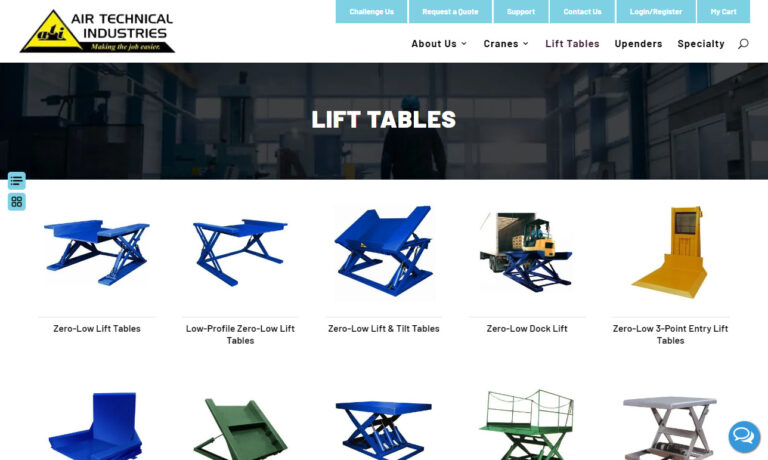

- Scissor Lifts: Characterized by a crisscross (scissor-like) mechanism, these lifts offer stable, vertical elevation. Scissor lifts are widely used in manufacturing, construction, and facilities maintenance for safe access to elevated workspaces.

- Hydraulic Car Lifts: Purpose-designed for automotive repair shops and parking solutions, these lifts raise vehicles for inspection, maintenance, and storage.

- Hydraulic Platform Lifts: Used to elevate goods or people between floors or work areas. These are common in warehouses, factories, and commercial buildings for efficient material handling.

- Hydraulic Freight Elevators: Heavy-duty elevators designed to move large, bulky loads vertically within industrial and commercial buildings.

- Hydraulic Table Lifts: Adjustable tables capable of lifting heavy objects to ergonomic working heights, improving worker safety and productivity in manufacturing and assembly environments.

- Patient and Accessibility Lifts: Compact hydraulic lifts designed for safe and comfortable movement of patients or individuals with mobility challenges in healthcare settings.

- Custom Hydraulic Lifts: Engineered to meet unique dimensions, load capacities, or operational requirements for specialized industries or applications.

Explore More: What types of hydraulic lifts are available?

Advantages of Hydraulic Lift Systems

Hydraulic lifts offer a range of benefits that make them the preferred choice for many commercial and industrial lifting applications. Understanding these advantages can help guide your selection process:

- High Lifting Capacity: Hydraulic systems can effortlessly lift extremely heavy loads, making them suitable for applications such as automotive lifts, freight elevators, and industrial equipment handling.

- Precision and Control: Operators can achieve precise positioning and smooth motion, critical for applications requiring accuracy and safety.

- Space Efficiency: Many hydraulic lifts have a compact footprint, enabling installation in areas with limited space while still providing powerful lifting capabilities.

- Safety: Hydraulic lifts are equipped with safety features such as pressure relief valves, locking mechanisms, and emergency lowering systems, ensuring safe operation even under challenging conditions.

- Reliability and Longevity: Well-designed hydraulic lifts are durable and require minimal maintenance compared to mechanical alternatives, delivering long-term value and consistent performance.

- Energy Efficiency: Hydraulic lifts typically consume less energy during operation, and the use of accumulators allows for energy storage and reduced wear on the power source.

- Adaptability: These lifts can be customized to suit a wide range of load capacities, lifting heights, installation environments, and control requirements.

Looking to improve operational efficiency or safety? Discover more about the benefits of hydraulic lifts for your facility.

Hydraulic Lift Power Sources: Hydraulics vs. Electric vs. Hybrid

While hydraulic lift systems are typically powered by hydraulic pressure generated via pumps and fluid movement, not all lifts are solely hydraulically powered. Some systems integrate:

- Electric Motors: AC or DC electric motors are commonly used to drive hydraulic pumps, with DC motors preferred for quieter, smoother operation and compatibility with battery-powered mobile lifts.

- Hybrid Systems: Combining hydraulic and electric power, these systems offer greater flexibility, efficiency, and redundancy, making them suitable for sensitive or mission-critical environments.

- Manual Operation: Smaller hydraulic lifts, such as portable jacks or patient lifts, may offer a manual pump option for use in the absence of electrical power.

Interested in the pros and cons of different lift power sources? Compare hydraulic, electric, and hybrid lift systems.

Key Components of Hydraulic Lift Systems

At their core, hydraulic lift systems consist of several integral components:

- Pistons: Move within cylinders to create the lifting or lowering action.

- Pumps: Pressurize the hydraulic fluid to transmit force throughout the system.

- Cylinders (Rams): House the pistons and convert fluid pressure into mechanical motion.

- Hydraulic Fluid: The medium for transmitting power; fluid choice affects performance, temperature range, and maintenance needs.

- Accumulators: Store hydraulic energy under pressure, providing backup power and smoothing out system demand.

- Power Source: AC or DC electric motors, batteries, or internal combustion engines.

- Valves and Controls: Regulate fluid flow, direction, and pressure to achieve precise and safe operation.

Learn more about key hydraulic lift components and maintenance.

Understanding Hydraulic Accumulators

Hydraulic accumulators are essential safety and performance devices within hydraulic lift systems. They function to store pressurized hydraulic fluid for use in case the hydraulic pump malfunctions, the engine shuts down, or the pump cannot keep up with demand. Accumulators help maintain consistent lift performance, dampen pressure surges, and act as a backup energy source during unexpected power loss. Proper accumulator sizing and maintenance are critical for system longevity and reliability.

Have questions about accumulator selection or troubleshooting? Explore our guide to hydraulic accumulators.

How to Select the Right Hydraulic Lift for Your Application

Choosing the optimal hydraulic lift involves evaluating several important criteria:

- Load Capacity: Assess the maximum weight the lift will need to handle, including all materials, equipment, or personnel.

- Lifting Height: Determine the required vertical travel distance for your application.

- Space Constraints: Measure available installation area and check for overhead obstructions or pit requirements.

- Cycle Frequency: Estimate how often the lift will be used to ensure the selected system meets duty cycle and durability demands.

- Speed: Consider how quickly loads need to be moved for your workflow efficiency.

- Safety Features: Look for pressure relief valves, locking mechanisms, emergency stops, and fail-safe controls.

- Power Source: Select between AC, DC, manual, or hybrid power based on operational environment, mobility, and noise considerations.

- Regulatory Compliance: Ensure the lift meets relevant safety standards (ANSI, OSHA, ADA, etc.) for your industry and region.

- Maintenance Needs: Evaluate ease of service, parts availability, and long-term support from the manufacturer.

- Customization: Some applications require tailored lift designs; consult with manufacturers about custom engineering options.

Not sure which hydraulic lift is right for you? Request a quote or consultation for expert advice tailored to your needs.

Hydraulic Lift System Safety and Maintenance

Regular inspection, preventative maintenance, and adherence to safety protocols are vital for the safe and efficient operation of hydraulic lift systems. Key safety tips include:

- Conducting daily pre-use inspections to check for leaks, unusual noises, or irregular operation.

- Ensuring all safety locks, brakes, and emergency controls are functional.

- Following the manufacturer’s recommended maintenance schedule, including hydraulic fluid changes and filter replacements.

- Training operators on proper use, load limits, and emergency procedures.

- Maintaining records of inspections, repairs, and incidents for compliance and liability purposes.

Interested in optimizing lift safety and reliability? Read our top hydraulic lift safety tips.

Cost Considerations and ROI for Hydraulic Lifts

When evaluating hydraulic lift systems, it’s important to factor in both initial investment and long-term operating costs. While hydraulic lifts may have a higher upfront cost than some mechanical alternatives, their durability, reduced maintenance requirements, and high lifting efficiency often result in a favorable total cost of ownership. Additional cost factors include installation, customization, power consumption, and required safety features.

For organizations seeking to maximize ROI, consider the following:

- Energy savings from efficient hydraulic systems

- Reduced downtime and maintenance expenses

- Improved productivity and throughput

- Enhanced safety reducing the risk of workplace injuries

Looking for a cost-benefit analysis or budgeting advice? See our guide to hydraulic lift pricing and ROI.

Frequently Asked Questions About Hydraulic Lifts

- What is the difference between hydraulic and mechanical lifts?

Hydraulic lifts use pressurized fluid to generate lifting force, offering smoother operation and higher load capacities, while mechanical lifts rely on gears, chains, or cables and may require more maintenance. - How often should hydraulic lifts be serviced?

Most manufacturers recommend scheduled maintenance every 3-6 months, but frequency depends on usage intensity and operating environment. - Can hydraulic lifts be customized for unique applications?

Yes, leading hydraulic lift manufacturers provide custom engineering to meet specific dimensions, capacities, and operational requirements. - Are hydraulic lifts suitable for outdoor use?

Many hydraulic lifts are designed with weather-resistant materials, making them suitable for outdoor use in construction, agriculture, and marine applications. - What is the typical lifespan of a hydraulic lift system?

With proper maintenance, hydraulic lifts can last 15-25 years or more, depending on application and usage. - How do I choose the right hydraulic fluid?

Fluid selection should be based on manufacturer recommendations, considering factors like temperature range, viscosity, and contamination resistance.

Have more questions? Browse our full hydraulic lift FAQ or contact our experts for personalized assistance.

Conclusion: Why Hydraulic Lifts Remain Essential Across Industries

In summary, hydraulic lifts remain indispensable across a wide range of commercial, industrial, medical, and mobility-related applications. Their unique ability to multiply force, adapt to various environments, and deliver safe, reliable, and efficient performance makes them the preferred choice for vertical and horizontal lifting challenges. Whether you’re upgrading an automotive shop, streamlining a warehouse, designing accessible facilities, or tackling heavy construction projects, hydraulic lift systems offer unmatched versatility and value.

Ready to find the best hydraulic lift system for your needs? Request a quote or contact our hydraulic lift experts today.

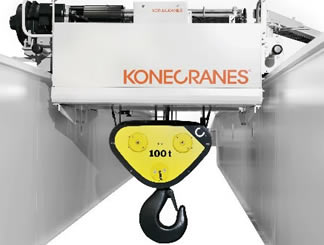

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services