More Hydraulic Lift Manufacturers

Hydraulic Lift Applications

Hydraulic lifts are essential across a diverse range of industries due to their robust lifting power, reliability, and adaptability. Their primary roles span manufacturing, construction (notably in roofing, masonry, and steelwork), the automotive and aviation sectors, material handling, warehousing, general transportation, shipping, and docking operations. In these fields, hydraulic lift tables and platforms streamline logistical workflows by enabling the efficient loading and unloading of goods, repositioning of warehouse materials for optimized storage, elevating workers safely to otherwise inaccessible heights, and supporting routine maintenance as well as heavy-duty material handling tasks.

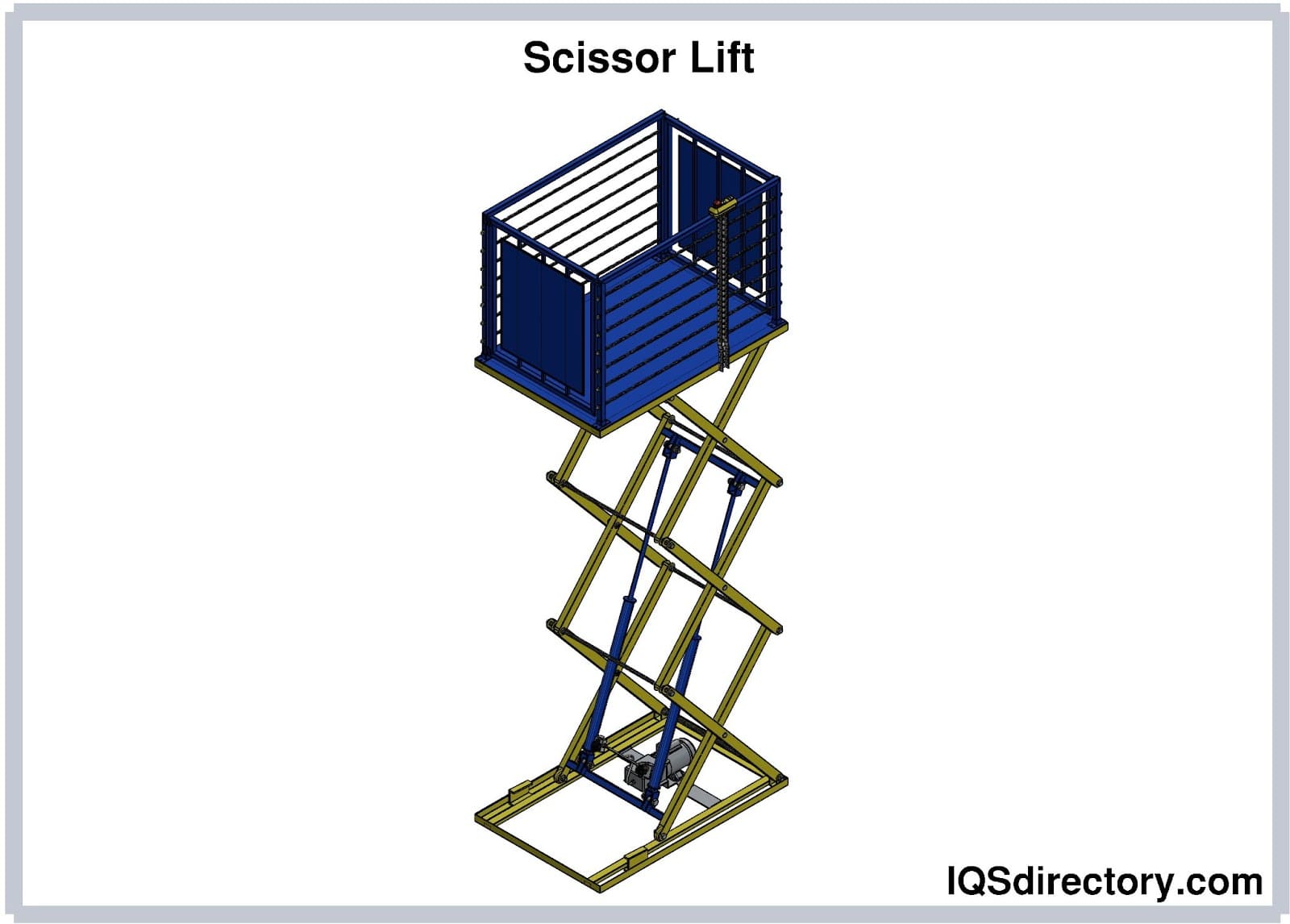

In logistics and warehouse environments, scissor lifts and hydraulic pallet lifts are indispensable for improving productivity and workplace ergonomics. They facilitate safe personnel elevation, reduce manual handling injuries, and boost throughput during inventory movement. In the automotive industry, hydraulic lifts are vital for vehicle maintenance, undercarriage inspections, and component assembly, while aviation relies on specialized hydraulic lifts for passenger boarding, luggage handling, and aircraft servicing.

Hydraulic lift technology also enhances accessibility in residential and healthcare settings. Home lifts, wheelchair platform lifts, and adaptive hydraulic systems grant individuals with limited mobility greater independence, meeting ADA (Americans with Disabilities Act) requirements and improving quality of life.

Are you searching for the best hydraulic lift solution for your business or facility? Explore our guide below to discover the different types of hydraulic lifts and find out which application best matches your operational needs.

History of Hydraulic Lifts

The evolution of hydraulic lift technology is a testament to human ingenuity in solving material handling and elevation challenges. Since ancient times, rudimentary lift tables and hoisting platforms enabled monumental construction projects, such as Roman amphitheaters and temples. These early lifts relied on counterweights, ropes, and human or animal power.

A seismic shift occurred with Joseph Bramah’s invention of the hydraulic press in 1795, which harnessed the power of pressurized fluid to amplify force—a principle at the heart of all modern hydraulic equipment. Bramah’s work revolutionized agriculture, industry, and construction by powering cranes, trains, and even early elevators. Sir William Armstrong’s development of the hydraulic crane in 1846 further expanded the reach of hydraulic machinery in dockyards and heavy industry.

By the Industrial Revolution, engineers refined hydraulic systems, culminating in the 1870 debut of the hydraulic elevator in New York City—a safer and more efficient alternative to unreliable steam-powered lifts. In the automotive realm, Peter Lunati’s 1925 invention of the fully hydraulic car lift transformed vehicle maintenance and repair, leading to the creation of the Automotive Lift Institute (ALI) to standardize safety and performance.

The hydraulic scissor lift, invented by Charles L. Larson in 1963, and Kaspar Klaus’s sidelifter innovation, further diversified lift technology by offering new solutions for vertical and lateral movement of heavy loads. The 1980s saw the introduction of the hydraulic scissor car lift, and by the early 2000s, four-post hydraulic vehicle platform lifts became industry staples. Today, the hydraulic lift industry continues to push boundaries, focusing on automation, ergonomics, energy efficiency, and user safety while meeting increasingly rigorous regulatory standards.

Curious about the origins of your hydraulic lift system? Learn more about the technological milestones that shaped today’s industry-leading hydraulic lifting equipment.

How Hydraulic Lifts Work: Principles and Components

All hydraulic lifts, from simple manual models to advanced automated systems, operate on the foundational principle of Pascal’s Law—applying force to an incompressible fluid within a closed system to multiply lifting power. At the core, a hydraulic cylinder filled with pressurized hydraulic fluid (usually oil) drives a piston rod upward, translating hydraulic energy into mechanical motion.

When hydraulic oil is pumped into the cylinder, the incompressible fluid forces the piston to rise, lifting the attached platform or load. Lowering is achieved by opening a valve, allowing the fluid to flow back into the reservoir under gravity. The basic system features two pistons of different diameters connected by an oil-filled pipe; a small force applied to the smaller piston is multiplied at the larger piston, enabling hefty loads to be lifted with minimal input.

Force Amplification in Hydraulic Systems

The force output of a hydraulic lift depends on the ratio of piston sizes. For example, applying 100 pounds of force to a 2-inch piston can generate up to 900 pounds of lifting force on a 6-inch piston, thanks to hydraulic multiplication.

Key Hydraulic Lift Components and How They Interact

- Hydraulic Fluids: Specialized oils or water-based liquids that transmit energy and lubricate system components.

- Hydraulic Valves: Regulate fluid flow, pressure, and direction, enabling precise control over lift movement.

- Hydraulic Circuits: The network of pipes, hoses, and valves orchestrating the movement of hydraulic fluid throughout the system.

- Hydraulic Motor: Converts hydraulic pressure into rotational energy for drive systems or auxiliary functions.

- Hydraulic Pump: Pressurizes hydraulic fluid, driving it through the system to the cylinder or motor.

- Hydraulic Cylinder: The primary actuator that converts pressurized fluid into linear motion.

- Hydraulic Pistons: Move within the cylinder to physically lift or lower the platform or load.

For a deeper dive into the science and mechanics behind hydraulic lifting, ask: How do hydraulic circuits ensure both safety and efficiency in modern lifts?

Hydraulic Fluids: Types and Selection Criteria

Hydraulic fluids are vital to system performance, acting as the medium for power transmission, lubrication, cooling, and corrosion prevention. Fluid choice impacts efficiency, lifespan, and safety of the hydraulic lift. Common hydraulic fluid types include:

- Mineral Oils: Widely used for their stability and excellent lubrication, especially in industrial environments.

- Synthetic Oils (e.g., PAO): Offer superior thermal and oxidation stability, making them ideal for high-temperature or high-pressure applications.

- Water-Based Fluids: Environmentally friendly but less effective as lubricants and more prone to evaporation or freezing.

- Glycol Ethers: Known for high lubrication and temperature resilience.

- Organophosphate Esters: Highly fire-resistant, used in hazardous environments.

- Silicone Oils: Withstand extreme heat, suitable for specialized industrial processes.

Key factors in fluid selection include operating temperature range, pressure requirements, environmental impact, compatibility with seals and components, and regulatory compliance. Always consult your lift manufacturer’s recommendations to ensure optimal performance and system longevity.

Are you evaluating which hydraulic fluid is best for your equipment? Compare fluid types for your application using our hydraulic fluid selection guide.

Hydraulic Valves: Types and Critical Functions

Hydraulic valves are the precision instruments that govern system operation and safety. They control the routing, pressure, and flow of hydraulic fluid, directly impacting how a lift operates. Major valve categories include:

- Directional Control Valves: Determine the path of fluid to extend or retract cylinders, raising or lowering the lift platform.

- Pressure Control Valves: Maintain safe system pressures, protecting components from overload or failure.

- Flow Control Valves: Regulate the speed of actuators for smooth, controlled lifting and lowering.

- Check Valves: Ensure fluid flows in only one direction, preventing accidental lowering or system backflow.

Proper valve operation, often triggered by electrical switches or manual levers, is essential for safe, repeatable lift movements. Malfunctioning valves can lead to erratic performance or unsafe conditions, underscoring the importance of regular inspection and preventive maintenance.

Want to troubleshoot or upgrade your hydraulic system? Read: What are the most common hydraulic valve issues and how can they be resolved?

Hydraulic Circuits and System Safety

A hydraulic circuit is the orchestrated network that ensures safe, efficient lifting and lowering. The process begins with the hydraulic pump pressurizing fluid from the reservoir, which is routed through control valves and delivered to the cylinders. The design of the circuit allows for fine-tuned adjustment of lift speed, load control, and direction of movement while incorporating fail-safes like pressure relief valves.

Safety features such as overload protection, emergency shut-off valves, and interlock systems are standard in high-quality hydraulic lifts. These measures prevent dangerous over-pressurization, accidental descent, or unintended operation, helping you comply with regulatory standards and reduce workplace accidents.

Need a safety checklist for your hydraulic lift circuit? Download our hydraulic lift safety inspection template for regular audits.

Hydraulic Motors: Powering Advanced Lift Systems

Hydraulic motors convert the energy of pressurized fluid into rotational mechanical energy, driving gears or wheels connected to the lift mechanism. This enables not only vertical movement but also auxiliary operations such as conveyor drives or rotating platforms. The ability to deliver high torque at variable speeds makes hydraulic motors ideal for demanding industrial applications.

Modern hydraulic lift systems may use integrated motor-pump units for improved efficiency, compact design, and enhanced control. Adjustable speed and reversible direction are valuable for tasks requiring precision positioning or continuous-duty operation.

Are you upgrading to a hydraulic motor-driven lift? See our comparison of electric versus hydraulic lift drives for industrial applications.

Hydraulic Pump: The Heart of Every Hydraulic Lift

The hydraulic pump is the primary driver that transforms mechanical input (from an electric motor or internal combustion engine) into hydraulic energy by pressurizing the system fluid. Pump types include:

- Gear Pumps: Reliable and cost-effective for moderate pressure and flow rates.

- Vane Pumps: Provide smoother flow and are suitable for variable-speed applications.

- Piston Pumps: Deliver high pressures and are used in demanding or heavy-duty systems.

The performance and reliability of the hydraulic pump directly affect lift speed, capacity, and energy efficiency. Choosing the correct pump size and type is essential for optimizing total cost of ownership and minimizing downtime.

Need help sizing a hydraulic pump for your lift? Use our interactive hydraulic pump sizing calculator.

Hydraulic Cylinder and Pistons: The Muscles of Lifting

Hydraulic cylinders convert the energy of pressurized fluid into straight-line (linear) motion. Inside, a piston attached to a rod moves within a sealed barrel, extending or retracting to lift or lower the platform. The cylinder’s bore size, stroke length, and material construction determine its load capacity, speed, and durability.

Hydraulic pistons are engineered to withstand high stresses and repeated cycling, making them ideal for continuous operation in industrial settings. Their precise movement ensures safe, smooth, and accurate load handling, from delicate electronic components to massive construction beams.

Selecting the right cylinder and piston combination is critical for maximizing performance and minimizing wear. Consider factors such as load weight, frequency of use, environmental conditions, and service requirements.

Need to specify replacement cylinders or pistons? Contact our technical support for guidance on hydraulic cylinder sizing and compatibility.

Types of Hydraulic Lifts: Matching Solutions to Your Needs

Hydraulic lifts are available in a multitude of configurations, each tailored to specific applications and operational requirements. Common types include:

- Hydraulic Scissor Lifts: Feature a crisscrossed, accordion-style support structure that extends for vertical elevation. Ideal for maintenance, warehousing, and construction tasks requiring substantial lifting height and stability.

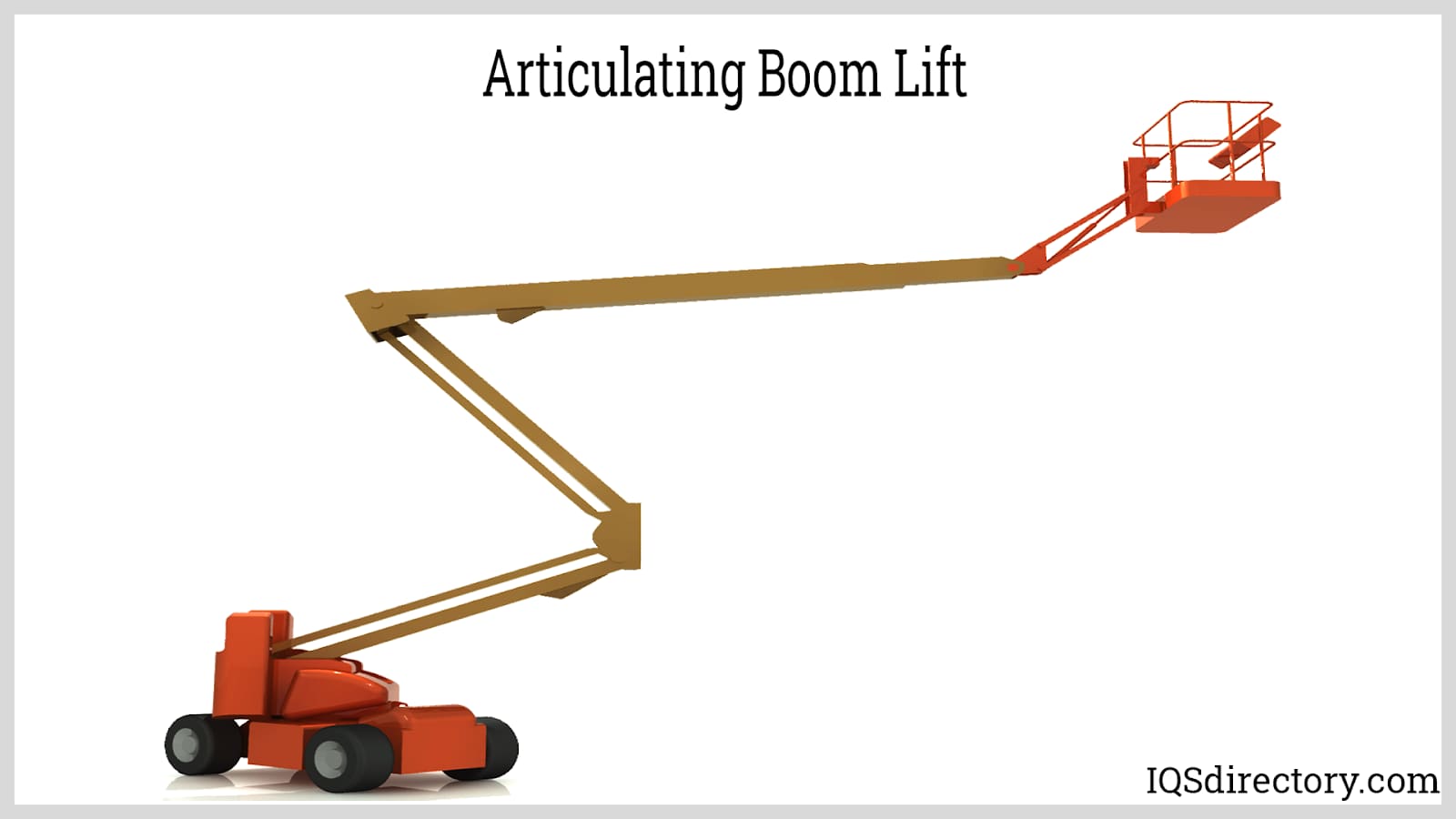

- Aerial Lifts (Aerial Work Platforms): Engineered for personnel access, these lifts can reach heights of 10 to 50 feet and are commonly used in warehouse racking, building maintenance, and lighting installation. Learn more about aerial lifts.

- Mobile Scissor Lift Tables: Mounted on casters for easy movement, they combine vertical lifting with mobility and are often equipped with tiltable platforms for ergonomic material transfer.

- Platform Lifts: Heavy-duty, large-scale lifts for moving oversized or heavy goods. Perfect for manufacturing floors and logistics centers.

- Pallet Lifts: Designed for the efficient elevation and transport of palletized materials in shipping, receiving, and warehouse environments. Find pallet lift solutions.

- Vehicle Lifts: Heavy-duty lifts for auto repair shops, truck maintenance, and fleet service centers. Capable of supporting vehicles ranging from compact cars to commercial buses and construction vehicles.

- Post Car Lifts: Feature multiple arms and vertical columns for secure, stable vehicle elevation. Commonly fixed installations with robust safety features. Explore vehicle lift options.

Not sure which hydraulic lift is right for your project? Ask: What are the advantages and limitations of each hydraulic lift type?

Hydraulic Lift Table Components: Anatomy of a High-Performance Lift

A hydraulic lift table comprises several interconnected components that work in harmony to deliver reliable lifting and lowering of heavy loads. Understanding each part helps users maintain, troubleshoot, and optimize their equipment:

- Hydraulic Fluid (Oil): Transmits power, lubricates moving parts, and dissipates heat.

- Hydraulic Valves: Govern the direction, speed, and pressure of fluid entering the cylinder.

- Hydraulic Roller: Facilitates precise valve actuation for responsive lift control.

- Hydraulic Pump: Pressurizes the fluid, generating lift force.

- Hydraulic Cylinders: Convert pressurized fluid into vertical motion.

- Rotary Joint: Maintains fluid flow to moving components without leakage.

- Drive Machine: Powers the system, often via an electric or hydraulic motor.

- Land Surface: Provides stable support for the lift, ensuring safety and performance.

Need help with hydraulic lift table maintenance? Browse our maintenance checklist for hydraulic lift tables.

How to Use Hydraulic Lifts: Best Practices for Safety and Efficiency

Safe operation of hydraulic lifts is critical in any environment. While each model may have unique features, the following general guidelines apply:

- Before activation, ensure the lift is stable—lock casters (if present) and inspect your surroundings for obstacles or personnel. Communicate intended use to nearby coworkers to avoid accidents.

- Start the lift using the designated control (switch, lever, or button). If the lift is mobile, unlock and reposition it as needed, relocking once in place. Engage safety bars or guards before lifting any load.

- Gradually elevate the load, carefully monitoring for unusual noises, jerky movements, or warning lights.

- Never exceed the manufacturer’s rated load capacity. Overloading can damage hydraulic cylinders, valves, and fluid seals, increasing the risk of sudden failure or workplace injury.

- Always follow the lift’s operating instructions and conduct routine inspections before use.

Looking for a detailed operating procedure for your hydraulic lift model? Download our step-by-step hydraulic lift operation guide.

Benefits of Hydraulic Lifts: Efficiency, Safety, and ROI

Hydraulic lifts deliver substantial advantages for businesses seeking to improve operational efficiency, workplace safety, and cost control:

- Versatility: Wide range of sizes and configurations to handle diverse applications, from delicate laboratory work to heavy construction lifting.

- High Load Capacity: Effortlessly handle loads from a few hundred pounds to several tons.

- Precision Control: Variable speed and height adjustment for accurate material positioning.

- Safety: Built-in safety features minimize risk of operator injury and equipment damage.

- Space Optimization: Compact designs maximize usable floor space in warehouses and manufacturing plants.

- Low Maintenance: Fewer moving parts and robust construction reduce maintenance frequency and cost.

- Cost-Effectiveness: Lower initial investment and maintenance costs compared to alternative lifting solutions, resulting in improved return on investment (ROI).

Interested in quantifying the benefits for your operation? Calculate your potential ROI using our hydraulic lift cost-benefit analysis tool.

Hydraulic Lift Design and Customization

Every application demands a unique hydraulic lift solution. Manufacturers offer extensive design and customization options to fit site-specific requirements:

- Material Selection: Stainless steel for hygiene-critical environments (food, pharmaceuticals), woven wire for lightweight applications, and rubber or composite materials for corrosion resistance.

- Mobility: Wheeled lifts for portability; fixed installations for production lines or high-capacity applications.

- Automation: Options range from manual to fully automated lifts with programmable controls and remote operation.

- Load Capacity & Height: Customization to support unique load weights and vertical travel distances.

- Additional Features: Custom colors, specialized coatings, warning lights, protective skirts, extra arms, and ergonomic foot controls.

Considering a custom hydraulic lift? Submit your specifications for a tailored hydraulic lift design proposal.

Uses of Stainless Steel Lifts: Industry-Specific Applications

Stainless steel hydraulic lifts are the gold standard for sectors demanding rigorous sanitation and corrosion resistance, including food processing, pharmaceuticals, chemical production, and cleanroom environments. Their non-porous, easy-to-clean surfaces comply with FDA, USDA, and GMP requirements while maintaining structural integrity under frequent washdowns and harsh cleaning agents.

- Ergonomic Ingredient Positioning: Automate the feeding of raw materials into batch or continuous processes, improving worker safety and process efficiency.

- Portable Tippers/Dumpers: Transfer bulk materials between containers, minimizing manual handling injuries.

- Material Transport: Move goods between workstations or storage areas with height-adjustable, wheeled lifts.

- Man Lifts: Provide stable, elevated work platforms for personnel in confined or sensitive environments.

- Pallet Inverters: Facilitate rapid pallet exchange and prevent settling in liquid-filled containers.

- Stackers: Efficiently stack heavy loads on high shelving, even in narrow aisles.

Need an FDA-compliant hydraulic lift? Filter our supplier directory by industry certifications and hygienic lift options.

Hydraulic Lift Safety and Compliance Standards

Safety and regulatory compliance are non-negotiable when selecting and operating hydraulic lifts. Adherence to standards such as OSHA (Occupational Safety and Health Administration) in the U.S., EN and BS EN in Europe, and ISO global specifications ensures legal compliance, minimizes risk, and protects workers.

Consult your supplier for specific certifications, and always verify that your equipment is labeled with manufacturer information and installation dates. Maintain detailed maintenance logs and conduct regular inspections to stay ahead of potential issues.

Top Hydraulic Lift Safety Tips:

- Follow manufacturer’s usage instructions and recommended load limits.

- Clearly label all equipment and maintain an up-to-date repair log.

- Keep bystanders clear and never operate the lift near overhead obstacles or power lines.

- Ensure work surfaces are clean and free of oil to prevent slips.

- Inspect hydraulic fluid levels and remove equipment from service if any malfunction occurs.

- Maintain a safe distance from electrical hazards and unstable terrain.

Looking for a compliance checklist? Download our up-to-date hydraulic lift compliance and safety guide for your industry.

Finding the Right Hydraulic Lift Supplier

Selecting a reputable hydraulic lift manufacturer is a critical decision for ensuring equipment quality, long-term support, and regulatory compliance. Our supplier directory offers comprehensive profiles with product details, industry expertise, and facility certifications. Use our contact forms for direct inquiries or to request competitive quotes. Our website previewer and streamlined RFQ process enable you to efficiently compare multiple suppliers and find the best fit for your business.

Ready to start your search? Browse our directory and use our RFQ tool to connect with top hydraulic lift manufacturers today.

For complementary equipment and solutions, visit our industry partners:

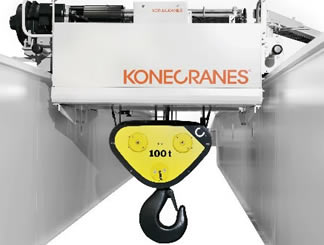

- Check out our Crane Manufacturers website

- Check out our Wire Rope website

Still have questions about hydraulic lift systems, applications, safety, or customization?

Search our knowledge base or contact us for expert assistance and recommendations tailored to your unique requirements.

What are the main applications of hydraulic lifts?

Hydraulic lifts are used across manufacturing, construction, automotive, aviation, warehousing, shipping, residential, and healthcare sectors for tasks such as material handling, personnel elevation, vehicle servicing, and improving accessibility. They enhance safety, productivity, and ergonomic efficiency in these diverse environments.

How does a hydraulic lift work?

A hydraulic lift operates on Pascal’s Law by applying force to an incompressible fluid within a closed system to multiply lifting power. Pressurized hydraulic fluid drives a piston inside a cylinder, elevating the platform or load. Lowering is achieved by releasing fluid back into the reservoir via valves for controlled descent.

What types of hydraulic lifts are available?

Common types include hydraulic scissor lifts, aerial work platforms, mobile scissor lift tables, platform and pallet lifts, vehicle lifts, and post car lifts. Each is designed for specific applications, such as accessing heights, moving palletized goods, or servicing vehicles.

How do I choose the right hydraulic fluid for my lift?

Select hydraulic fluid based on your system’s temperature range, pressure needs, environmental impact, and component compatibility. Options include mineral oils, synthetic oils, water-based fluids, glycol ethers, organophosphate esters, and silicone oils. Always follow your lift manufacturer’s recommendations for optimal performance and longevity.

What are critical safety tips for using hydraulic lifts?

Always follow manufacturer instructions and rated load limits, label equipment clearly, maintain updated repair logs, keep work areas clean and dry, inspect fluid levels, and perform regular maintenance. Ensure equipment complies with OSHA or relevant regional safety standards to minimize risks.

What are the major components of a hydraulic lift table?

A hydraulic lift table consists of hydraulic fluid, valves, rollers, pumps, cylinders, rotary joints, the drive machine, and a stable land surface. These components work together to provide safe, efficient lifting and precise load positioning.

Why are stainless steel hydraulic lifts used in the food and pharmaceutical industries?

Stainless steel hydraulic lifts are resistant to corrosion and easy to clean, making them ideal for applications where sanitation is essential. They comply with FDA, USDA, and GMP requirements, maintaining safety and hygiene during frequent washdowns and in harsh environments.

How can hydraulic lifts be customized for specific applications?

Hydraulic lifts can be tailored through material selection, mobility options, automation features, load capacity, vertical travel customization, and additional safety or ergonomic components. Manufacturers often offer custom designs to meet the unique needs of different industries and workflows.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services