Even a small car is very heavy, so a vehicle lift needs to be strong and reliable to prevent accidents and damage. Mechanics use vehicle lifts that have a frame consisting of two or four strong metal posts that are firmly bolted into the ground.

Arms that can be raised and lowered extend from the post and create four points of contact underneath the vehicle so that it can safely be raised and lowered to the desired height.

It is important that these four points of contact underneath the vehicle are even so that the weight is not unequally distributed once the car leaves the ground, causing it to tip forwards or backwards.

Some lifts use heavy duty chains attached to a rotating sprocket powered by a motor to raise and lower the arms of a lift, but for high weight capacities hydraulic force is usually used. Heavy duty commercial trucks and equipment can weigh over 30,000 pounds, so a strong lifting force is absolutely essential.

In a hydraulic lifts, each post is fitted with a long cylinder and a piston that moves up and down on the cylinder when pressure is applied by the hydraulic fluid.

The operator simply lines up the vehicle above the lifting points and then uses controls to raise and lower the unit. Instead of lifting points that go underneath the vehicle, some lifts have ramps and a car can be driven right on to them.

This does not allow for the wheels to be removed from the car, but it does provide quick and easy access for things like oil changes and muffler repairs.

Lifting equipment can be customized to meet the needs of the industry it will be used in. For example, a bus repair shop will need very heavy duty equipment that is made to handle the dimensions of a bus.

A four post vehicle lift could still be used, but the posts will have to be installed farther apart and the hydraulic motor will have to be strong enough to lift and hold such a large object.

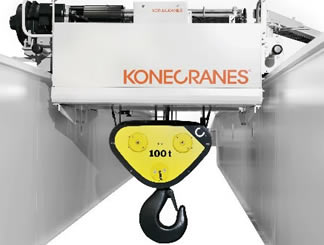

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services